Tungsten Alloy Rivet Bucking Bar Orientation

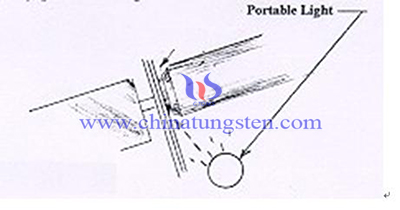

1.Rest tungsten alloy rivet bucking bar on inserted rivet and try to locate its point of balance.

2.With gun set in place, use rivet bucking bar to push rivet (and gun assembly) outward. Tungsten alloy rivet bar will then register at right angles to the rivet as it comes to rest on the aluminium.

3. Push rivet back into place with gun set and reposition rivet bar, if necessary, to maintain its point of balance on the rivet. (repeat steps 2 and 3 until point of balance is determined). Often the index finger can be placed on the back of the rivet bar directly opposite the rivet tail. It then becomes the 'sensor' for correct bar position.

4. Pressure is held on gun while riveting. Tungsten alloy rivet bucking bar is held with only moderate force (otherwise rivet may be set with head proud of surface). A rubber grommet may be used over the rivet tail to assist in squeezing parts together during riveting. It acts as a 'pressure plate'.

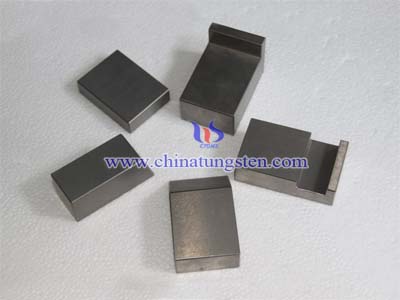

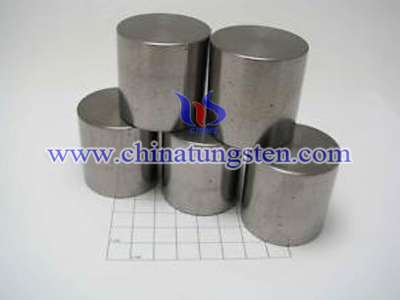

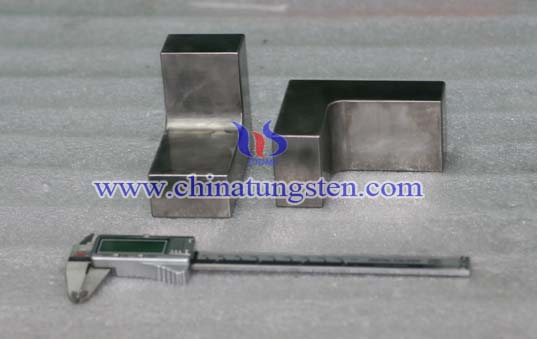

At Chinatungsten Online, tungsten alloy bucking bars are normally made from tungsten heavy alloy. All edges are deburred and working surfaces are polished for troubles-free use. This helps to prevent marring of formed bucktails. Please notice that never hold a bucking bar in a vise unless the vise jaws are equipped with protective covers to prevent marring of tungsten alloy bucking bar.